SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue 7

July 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue 7

July 2002

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, July 16th, at 7:00 p.m. in the

Duck River Electric Building, Dechard, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice

Berry 454-3815 Design

Phil Bishop

967-4626 Finishing

Tom

Church 967-4460 Turning

Harry May

962-0215 Carving

Bob

Reese 728-7974 Sharpening

Ross Roepke

455-9140 Joinery

Maurice Ryan 962-1555

Health and Safety

List of

Club Officer

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

CALENDAR of EVENTS

Coffee County Fair : 3rd week in September

Fall seminar :October 19

Christmas party: December 6

Dovetail Keys

Perhaps no other joint has more strength or better looks than

a corner joined by through dovetails. But here's a much

simpler joinery process that comes pretty close. With just a

router table and a bare-bones homemade jig, you can

crank out terrific-looking box corners like the one above.

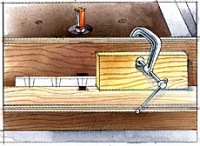

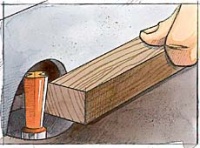

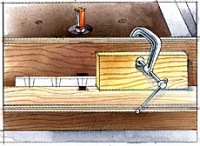

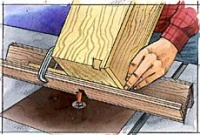

1. The jig above mounts to a miter gauge that slides in the miter slot

of a router table. Built to

the length shown, on most router tables it will handle boxes with sides

up to about 24" wide.

You can tailor the length to better suit your router table and to accommodate

smaller or larger boxes.

The miter slot-to-router bit spacing on your table may affect

the exact placement of the screws.

Be sure to put them where the router bit will not cut into them. (Before

you build this jig, please

read the next step and note.)

2. Mount a dovetail bit in your table-mounted router. We used an 11/16"-diameter

bit with an 8° cutter

angle anda 1/2" shank for the dovetails shown in the 3/4";-thick stock

of the corner. Most dovetail bits

will work, and you may want to consider using smaller bits for thinner

stock. Raise the bit so it will cut

to the correct approximate depth through your workpiece

sitting in the jig.

Mark the location where the shank of the dovetail bit will pass through

the jig in the

following steps. You need to remove the stock in this area of

the jig so the bit can pass through it.

We did so with a dado set as shown above. Make this cut through only

the "V" portion of the jig—do not

cut through the vertical piece that mounts to the miter gauge. You

also could make this cut by sawing

a series of kerfs with a handsaw and chiseling out the waste.

Note: If your table has a plunge router, it may be impossible

to raise the bit high enough to make a

full-depth cut. Also, the shorter shanks on smaller bits may prevent

the bit from cutting high enough.

In that case, you may have to make the jig from 1/2" plywood.

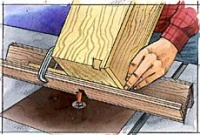

3. Pass the jig through the spinning dovetail bit as shown.

The bit's shank should prevent the bit from passing through the

back side of the jig.

4. Assemble a mitered corner from scrap stock of the same thickness

as the wood used in your box.

Use this test piece to fine-tune the height of the router bit. Then,

on the inside of the "V", mark the

center of the dovetail cut as shown.

5. On a piece of paper that's as long as your box corners, lay out

the position of the dovetails.

You can space the dovetails evenly or unevenly, but it usually looks

best to have a symmetrical

arrangement. For our box, we put one dovetail in the exact center,

with equal spacing between the dovetails.

The space between the end dovetails and the ends of the corner equal

half of the space between the dovetails.

Mark the dovetail centers.

Position your layout on the inside of the jig's "V" as shown, with

the center of the

right-most dovetail aligned with the center mark on the jig. Position

and clamp the block

at the end of the paper layout.

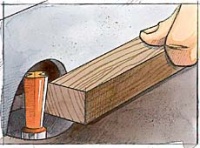

6. Place your box in the jig, butt it against the stop, turn on the

router, and pass the V

portion of the jig through the bit as shown. After making the cut,

lift the workpiece off

the jig and pull the jig back through the bit. Do not leave the box

in the jig when you

pull the jig back—doing so may enlarge the dovetail cut. Make this

cut on each of the

box corners (four total cuts).

7. Rotate the box 180° so its bottom faces in the opposite direction

it faced in the

previous step. Butt the box against the stop, and again cut each of

the four corners.

Rotating the box in this fashion ensures symmetrical spacing. Move

the clamped

stopblock as necessary to make the remaining cuts.

8. Measure the depth of the dovetail cuts as shown. Your dovetail key

stock should be

1/16" thicker than the depth of the dovetail cut. Rip this stock so

it's 1/16"; wider than

the widest part of the dovetail cut.

9. Using the same dovetail bit as before, adjust it 1/16"; higher than

the thickness of

your dovetail-key stock. Adjust the fence on your router table so the

bit just barely cuts

into the key stock at table height as shown.

Pass the stock through the bit. At the end of the cut you will get

a small amount of

snipe—you'll cut this off later.

10. Rotate the key stock end for end, keeping the same face down. Cut

the other edge.

Test the fit of this stock in the dovetail cuts. (Slide the unsniped

portion of the stock

into the dovetail cut.) The stock should be slightly too wide. Adjust

the fence forward

just a hair and recut the stock. Do this until the stock fits tightly

in the dovetail cuts. Cut

off the sniped ends.

11. Cut the key stock into lengths about 1/4" longer than the dovetail

cuts. Apply glue

to the dovetail cuts and slide the keys into them, leaving about 1/8"

extra key length at

both ends of the dovetail cuts.

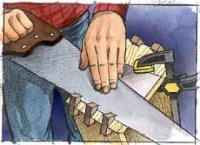

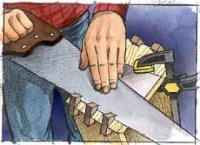

After the glue sets, saw off the excess key stock. A special flush-cutting

handsaw works

well, or you can use a typical handsaw if you protect the box with

a sheet of card stock

as shown.

FOR SALE

The following Craftsman tools;

12 in. Drill Press $130.00

10 in. Table Saw $250.00

Wood Shaper $175.00

14 Shaper Cutters $100.00

12 in. Bandsaw $200.00

Central Machinery 8 in. grinder $75.00

Contact Henry Davis

or at: 393-3191

July Meeting Program

Sherwin Williams, representative John Carter from McMinnville will be

presenting the program on July 16, for the Tennessee Valley Woodworker

Club. The subject will be the chemical coatings used in wood finishing.

The Fall Seminar on Joinery

will be held at Dean and Andy's shop on October

19. Ken Gould has agreed to serve as Chairman, with Bob Lowrance

and Steve Shores as Committee Members. The presenters will come from the

membership.

Bur Oak

A Tree No Longer

Than Its Roots

Were it not for the bur oak, pioneers in the Midwest would have been greeted by nothing but waving prairie

grass. Instead, they also were welcomed by invitingly open groves of wide-spaced

trees. Beneath the trees' dropping boughs grew a soft greencarpet. What a relief from

the East's tangled forest! Yet, little did the pioneers know of the great battleground

they had entered.

Botanists now understand that the bur oak—called that because of the

fuzzy cap on its acorn—was in constant combat with the tall prairie grass.

In periods of dryness, the grass advanced. When it was wet, the forest

gained, led by the bur oak.

Prairie fires, too, kept the oaks at bay. Then, with settlement, came cattle

to pack down the soil so acorns had trouble sprouting. Livestock also ate

the young seedlings' leaves. Yet, the bur oak survived due to its

remarkable roots.

If you were to somehow peer beneath the ground under a bur oak, you'd

discover a vast system. A relatively short taproot soon turns to a

spreading maze of thick, horizontal roots. Each of the horizontals sends

capillary roots down and up until the size of the entire growth below ground

equals that of the tree above! Such a root system rises to penetrate even

the deep-rooted prairie grasses to catch the slightest rainfall and remain

in

competition. In fact, the bur oak's prime competitor is another bur oak.

That's why they always grow some distance apart—the diameter of each

tree's roots determining their closeness.

NAME TAGS

The subject of name tags came up at the last meeting. Our name tags

were made by K&S TROPHIES , 510 Country Club Drive , Tullahoma.

They were about $5.00 including tax the last time we checked. When in Tullahoma

you can go by and have one made. The tags are 1" x 3" with white letters

on a blue background. Just tell the folks that you want a Tennessee Valley

Woodworkers name tag. If you are never in Tullahoma, Henry Davis will be

happy to take care of it for you, see him at the meeting or give

him a call at 393 - 3191.

Mini Lathe Give Away.

To show our appreciation to our loyal and faithful members your Executive

Committee has again this year decided to give a prize to one lucky member.

To be eligible to win the lathe just sign the drawing register at each

regular club meeting that you attend between now and December. That means

that if you attended the January meeting and attend every meeting from

now through November your name will be in the drawing 11 times.

WEB

SITES of INTEREST

Scott

Phillips Video Help sessions

Arrowmont

School of Arts and Craft

Loyd

Ackerman's Page

WOOD

ONLINE newsletter

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

Russell Brown's Web Page

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue 7

July 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue 7

July 2002

Editor: Tom Gillard Jr.

![]()

![]()

![]()