SPLINTERS

Tennessee Valley Woodworkers

Vol. 17/ Issue1

January 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue1

January 2002

Editor: Tom Gillard Jr.

Meeting Notice:

The next meeting of the TN Valley Woodworkers

Will be held, January 15th at 7:00 p.m. in the

Duck River Electric Building, Decherd, TN

All interested woodworkers are invited!

The following people have agreed to serve as contacts for their particular

skills. If you have questions, suggestions

for activities, or other comments relating to these skills, please

call these folks. Their interest is to help the

club better serve their area of expertise. Your participation

with them will help them achieve that goal.

Alice Berry

454-3815 Design

Phil Bishop

967-4626 Finishing

Tom Church 967-4460

Turning

Harry May

962-0215 Carving

Bob Reese

728-7974 Sharpening

Ross Roepke

455-8310 Jointery

Maurice Ryan 962-1555

Health and Safety

List of

Club Officer

President: Bob Leonard

V. President: Doyle McConnell

Secretary: Barbara Keen

Treasurer: Henry Davis

Publicity: Maurice & Ruth Ryan

Newsletter Editor: Tom Gillard Jr.

GOD BLESS AMERICA!

With the flying of flags comes the problem of what to do with the flags

that become tattered and torn due to use. The proper way of disposing

of these emblems of our Country is to retire them with dignity. This

usually involves burning them. The Boy

Scouts can offer their services if you have a flag that need to be

retired. There are three members of our club that are also members

of the BSA. Danny Bean, Steven Savelle, and Tom Gillard. Please

bring your flag to one of us if needed. Thanks

On behalf of the club I’d like to thank everyone that has helped this

club be so successful this past year. Without your help we wouldn’t

have had such a productive year. Lets do it again this year!

January meeting Program

David Duggin will make a presentation on recognizing and restoring "Tennessee

Furniture". David lives in Woodbury's oldest house and is a dealer of high

end period antiques.

Making Box Joints

Before the advent of cardboard boxes, manufacturers joined the sides

of thin wooden boxes with these joints because they were strong and fast

to make. Today, box joints have taken on practical and decorative roles

in projects ranging from jewelry cases to hope chests. After you build

the jig featured in the Box-Joint Jig Project, follow these steps and see

firsthand how easily you can master this joinery method.

1. Before you cut the actual box joints, keep in mind that the width

of your box sides must be an increment of the finger width. Otherwise,

you’ll wind up with less-than-pleasing partial fingers at the bottom of

your box. So, in the example of 1/4"-thick stock discussed

here and in the jig-building article, the width of the workpieces

must be an increment of 1/4" (such as 5", 5 1/4", 5 1/2",

etc.).

2. Mark the front, back, and side pieces of your box. Also, mark the

top edge on each of these pieces.

For each box you make, you cut the sides consecutively, and the front

and back consecutively. It doesn't matter which pair you do first, so we'll

start with the sides.

For all of the following cuts, hold the top edge of the workpiece toward

the jig pin for the first cut. Now, put hand pressure on the jig to hold

its miter-gauge bar firmly against the right side of the tablesaw channel.

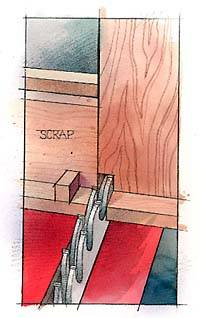

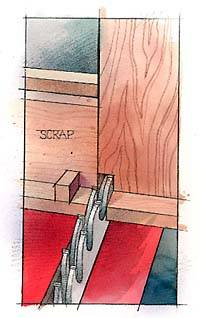

Make the first cut as shown above. Place the just-cut notch over the jib

pin and repeat to cut fingers along the full width of the workpiece. Cut

the other side piece in the same fashion.

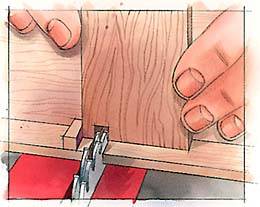

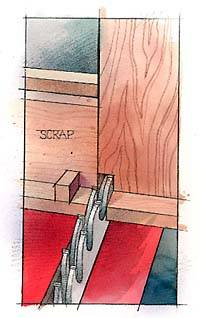

3. Before you cut the front and back, cut one notch into a scrap piece,

just as you cut the first notch into the side piece earlier. Position this

notch over the pin as shown at left, and butt the top edge of the front

piece against the scrap before making a cut.

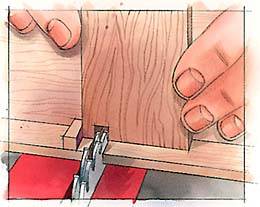

Make the remaining cuts in the front piece by removing the scrap, placing

the notch over the pin, and proceeding as described earlier. Cut the back

piece just as you cut the front.

4. To join your box pieces, apply glue to all of the mating surfaces

with a small brush. Tap the joints together with a rubber mallet if necessary.

Clamp the box together as shown above. (You may need to position a clamp

diagonally to square the box.)

Note that we used scrap pieces on each side of the corners to evenly

distribute the clamping pressure along the joint. Wider boxes may require

additional clamps.

After the glue dries, sand the fingers flush with the sides, front,

and back. Be careful not to round over the corners.

Eagan, Minnesota is south of Minneapolis and St. Paul.

Eagan just made forest

archaeological history when a drilling operation dug up

a piece of spruce

tree from 300 feet underground. Glaciers buried

this spruce forest way before

there were humans in North America. Scientists estimate

the wood to be

between 50,000 and 2 million years old.

The very interesting part is that the wood examined was

determined to grow at

a rapid rate of "3/8 of an inch in 30 years". The

cold that enveloped the

northland left only weeks of annual growing season.

It is really hard for me to fathom a glacier that dumps

300 feet of soil over a

forest. Experts suggest it was soil donated by the

Lake Superior basin.

Notice from the Treasurer:

DUES are due.

$10 for singles

$15 for families

Ailanthus

The tree that you really don't want to grow

For some unknown reason, the tree that many people call "tree of heaven"

or "paradise tree" after its Chinese local name, was brought to North America

from the Far East in the late 1700s. The bearer must have meant well, for

the ailanthus (Ailanthus altissima) isn't a terrible-looking tree. It grows

straight-to 60' or 80' tall-and quickly.

You'll find it in a wide "natural" range that stretches from the Plains

States to the East Coast and northern Michigan to Florida's panhandle.

In fact, heat or cold doesn't hinder this species much. Nor poor soil.

Nor city smog and smoke. Even dryness won't bother it. And the tree can

survive submergence in salt water. So, there's little to stop its propagation

(it spreads by seeds and sprouts from its deep root system). In many places,

the ailanthus has become a real nuisance by aggressively crowding out native

or ornamental species.

So why give this tree a bad rap? For one thing, it stinks. The blossoms

of the male ailanthus produce a stench. The leaves and wood also have a

formidable and unpleasant odor. And, it's not a very convincing shade tree.

Nor does ailanthus live long-maybe 75 years. Lastly, ailanthus wood looks

like white ash, but is weak and brittle.

Ailanthus' only claim to fame is that it is the tree referred to in

the book and motion picture A Tree Grows in Brooklyn. Unfortunately, it

really does.

Tip of the Day

Miter nice

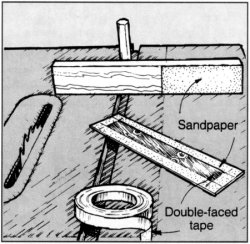

The slick metal surface of a miter gauge often is the culprit when wood

slides into the tablesaw blade.

TIP: To prevent wood from sliding, use double-faced tape to affix medium-

or fine-grit sandpaper to the face of the miter gauge of any power tool.

You can easily replace the tape and sandpaper when necessary.

—Bill Roberts, Angola, Ind.

Visitors at the December meeting:

Don Miller: Manchester

Lowell Johnson: Tullahoma

New Member:

David Jones: Manchester

-------------------------------------------------------------------------------

***************************************

"Briggs Paint on Atlantic street in Tullahoma will be carrying natural

color Deft Oil in gallon ($22.50) and Quart ($7.99) sizes as a test marketing

project. They should have it on the shelf before the end of January.

They will continue to carry it, if there is a demonstrated demand,

and maybe expand to carry the colors as well. See Jeff at the store

for questions or comments."

********************************

WEB

SITES of INTEREST

Arrowmont

School of Arts and Craft

WOOD

ONLINE newsletter

Falls Mill

Appalachain

Center for the Arts

Forest

Products Lab. 1999 Wood Handbook

Highland Hardware

Woodworker's

Journal

WOOD

Online TVWW page

Kevin's Woodturnings

The Oldham Company

The Woodworker's Choice

Russell Brown's Web Page

Saw Blade Sharpening Services: Branching Out is now offering their

services as a drop off spot to have your saw blades sharpened. The

blades will be picked up (Tuesdays), sharpened, and dropped back off at

Branching Out. The Leitz Tooling Systems out of Collierville, TN

will do the sharpening. Call (393-0525) or stop by for details.

10 % OFF Fine Woodworking

10 % OFF Fine Woodworking

Books from Taunton Press

…We’re open Monday thru Saturday

Webmaster:

Tom Gillard Jr.

Vol. 17/ Issue1

January 2002

Editor: Tom Gillard Jr.

Vol. 17/ Issue1

January 2002

Editor: Tom Gillard Jr.

![]()

![]()

![]()